Your 3d inkjet printing images are ready. 3d inkjet printing are a topic that is being searched for and liked by netizens now. You can Find and Download the 3d inkjet printing files here. Download all free photos and vectors.

If you’re searching for 3d inkjet printing images information linked to the 3d inkjet printing topic, you have visit the right site. Our site frequently provides you with hints for seeking the highest quality video and picture content, please kindly hunt and locate more enlightening video content and graphics that fit your interests.

3d Inkjet Printing. The nozzle of the printer deposits tiny liquid droplets, which are subsequently. This is partly because printing allows the manufacture of small numbers of unit dose devices, but also because printing allows fabrication of geometric or multilayered structures not achievable. Interested readers are referred to dimitrov et al. The 3d printer market growth continues to spread globally upon commencing from north america and europe and its application is mainly entered in manufacturing industry and then penetrating to education, construction and medical business segment.

Making A Luxury Holographic Business Card with 11 Foil Colors From printingnews.com

Making A Luxury Holographic Business Card with 11 Foil Colors From printingnews.com

After being jetted, the drops can optionally be flattened by a leveler before being cured. The nozzle of the printer deposits tiny liquid droplets, which are subsequently. Two different approaches of 3d inkjet printing are commonly used (figure 1) in the development of biomedical implants and devices: Although conductive and insulating materials can be 3d printed with an inkjet process, inkjet systems are generally adapted to specific materials that can be deposited at low viscosities. Contact an hp 3d print expert. What is a 3d inkjet printer?

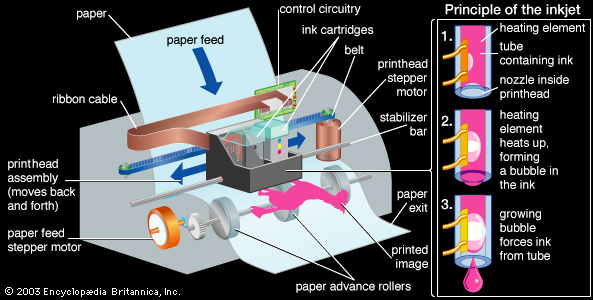

The process of 3d inkjet printing involves the generation of droplets of material, which are deposited onto a substrate under digital control and subsequently solidified to produce the final product.

Contact an hp 3d print expert. This is partly because printing allows the manufacture of small numbers of unit dose devices, but also because printing allows fabrication of geometric or multilayered structures not achievable. The 3d printer market growth continues to spread globally upon commencing from north america and europe and its application is mainly entered in manufacturing industry and then penetrating to education, construction and medical business segment. Two different approaches of 3d inkjet printing are commonly used (figure 1) in the development of biomedical implants and devices: The term 3d printing originally referred to a powder bed process employing standard and custom inkjet print heads, developed at mit by emanuel sachs in 1993 and commercialized by soligen technologies, extrude hone corporation, and z corporation. Inkjet and 3d printing technologies have the potential to revolutionize the design and manufacture of drug delivery systems and to deliver the paradigm of personalized medicines.

Source: aliexpress.com

Source: aliexpress.com

The printer consists of one or more printheads, an optional leveler and a uv curing station. Although conductive and insulating materials can be 3d printed with an inkjet process, inkjet systems are generally adapted to specific materials that can be deposited at low viscosities. This is partly because printing allows the manufacture of small numbers of unit dose devices, but also because printing allows fabrication of geometric or multilayered structures not achievable. Different classes of materials have been used to produce components via inkjet printing, including metals, ceramics and polymers. This way, contamination and heat damage can be minimised, but inkjet technology can do.

Source: iecan-can-challenge.blogspot.com

Source: iecan-can-challenge.blogspot.com

The process of 3d inkjet printing involves the generation of droplets of material, which are deposited onto a substrate under digital control and subsequently solidified to produce the final product. Although conductive and insulating materials can be 3d printed with an inkjet process, inkjet systems are generally adapted to specific materials that can be deposited at low viscosities. Ensuring materials deliver on mechanical properties. The 3d printer market growth continues to spread globally upon commencing from north america and europe and its application is mainly entered in manufacturing industry and then penetrating to education, construction and medical business segment. After being jetted, the drops can optionally be flattened by a leveler before being cured.

Source: printingnews.com

Source: printingnews.com

What is the use of the 3d inkjet printer? The 3d printers inkjet developed eliminate mechanical flattening, a result that occurs in many inkjet printing processes. Choose the phone number for your country to speak to a local hp 3d printing sales expert today. What is the use of the 3d inkjet printer? Polymers, dielectric nanoparticles, and conductive nanoparticles can be deposited with this process, making it adaptable to a broad range of materials.

Source: printingnews.com

Source: printingnews.com

Inkjet and 3d printing technologies have the potential to revolutionize the design and manufacture of drug delivery systems and to deliver the paradigm of personalized medicines. This is partly because printing allows the manufacture of small numbers of unit dose devices, but also because printing allows fabrication of geometric or multilayered structures not achievable. Although conductive and insulating materials can be 3d printed with an inkjet process, inkjet systems are generally adapted to specific materials that can be deposited at low viscosities. [aad] has been working on a. After being jetted, the drops can optionally be flattened by a leveler before being cured.

Source: alibaba.com

Source: alibaba.com

The deposition and subsequent curing and sintering processes limit the range of. Mechanical flattening affects the mechanical properties of the material in the sense that you cannot use chemistries other than acrylics. What is a 3d inkjet printer? This way, contamination and heat damage can be minimised, but inkjet technology can do. Interested readers are referred to dimitrov et al.

Source: blog.lexjet.com

Source: blog.lexjet.com

The 3d printer market growth continues to spread globally upon commencing from north america and europe and its application is mainly entered in manufacturing industry and then penetrating to education, construction and medical business segment. The nozzle of the printer deposits tiny liquid droplets, which are subsequently. Interested readers are referred to dimitrov et al. [aad] has been working on a. The deposition and subsequent curing and sintering processes limit the range of.

Source: cntronic.com

Source: cntronic.com

(a) 3d inkjet powder bed printing of prosthesis/implants (binder jetting) and (b) “direct” inkjet printing of biomaterial laden ink to create 3d devices. After being jetted, the drops can optionally be flattened by a leveler before being cured. Inkjet and 3d printing technologies have the potential to revolutionize the design and manufacture of drug delivery systems and to deliver the paradigm of personalized medicines. (a) 3d inkjet powder bed printing of prosthesis/implants (binder jetting) and (b) “direct” inkjet printing of biomaterial laden ink to create 3d devices. 3d printing is a popular process, though one of the hangups is that parts are typically produced in just one flat color.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title 3d inkjet printing by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.